ACCRA™ Packaging Advantages

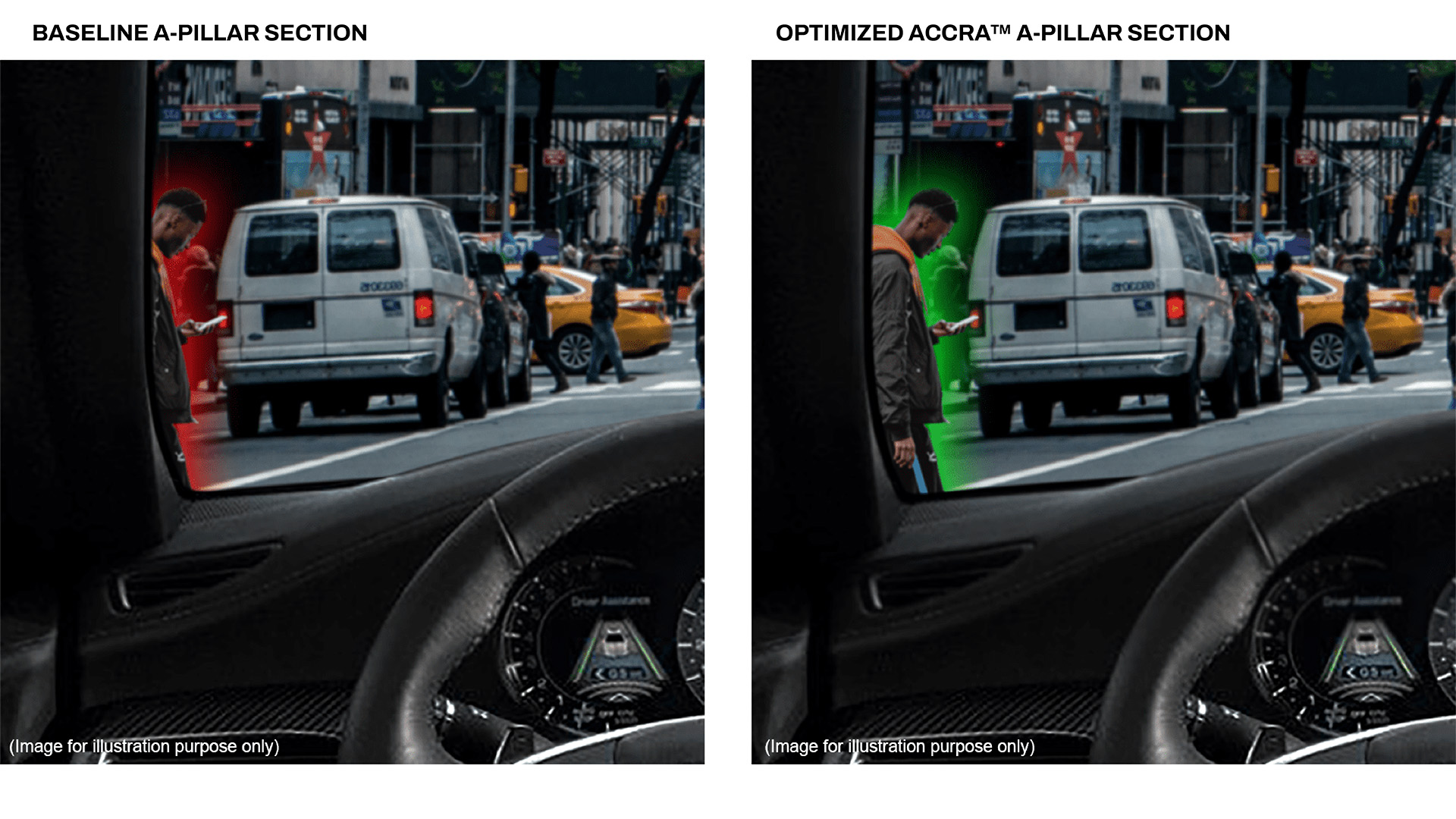

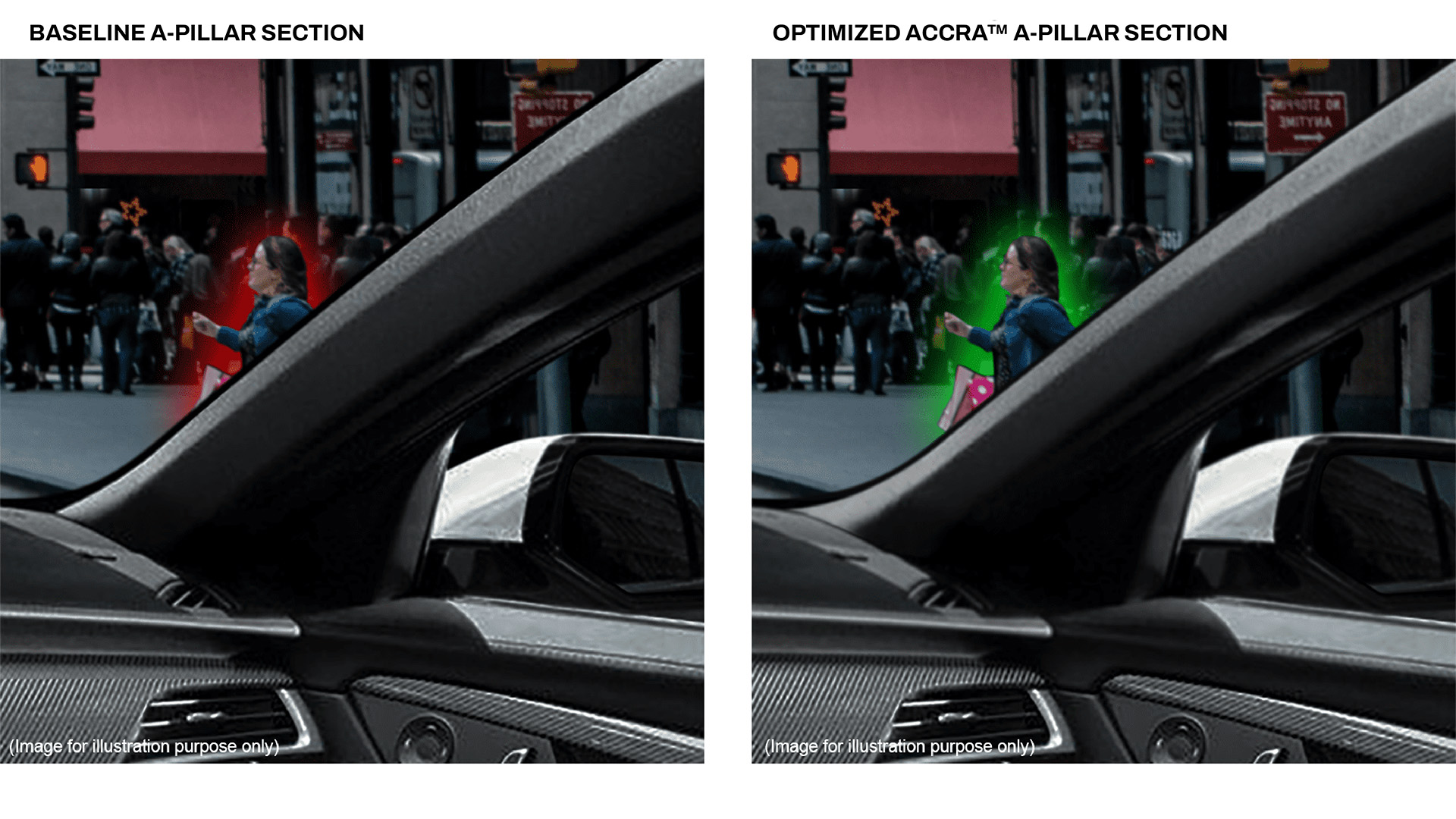

Minimizing A-pillar Vision Obstruction

Minimizing A-pillar vision obstruction while meeting vehicle crash and roof-crush requirements is a major challenge during vehicle development. Our ACCRA™ hot-blow-form technology solves this problem.

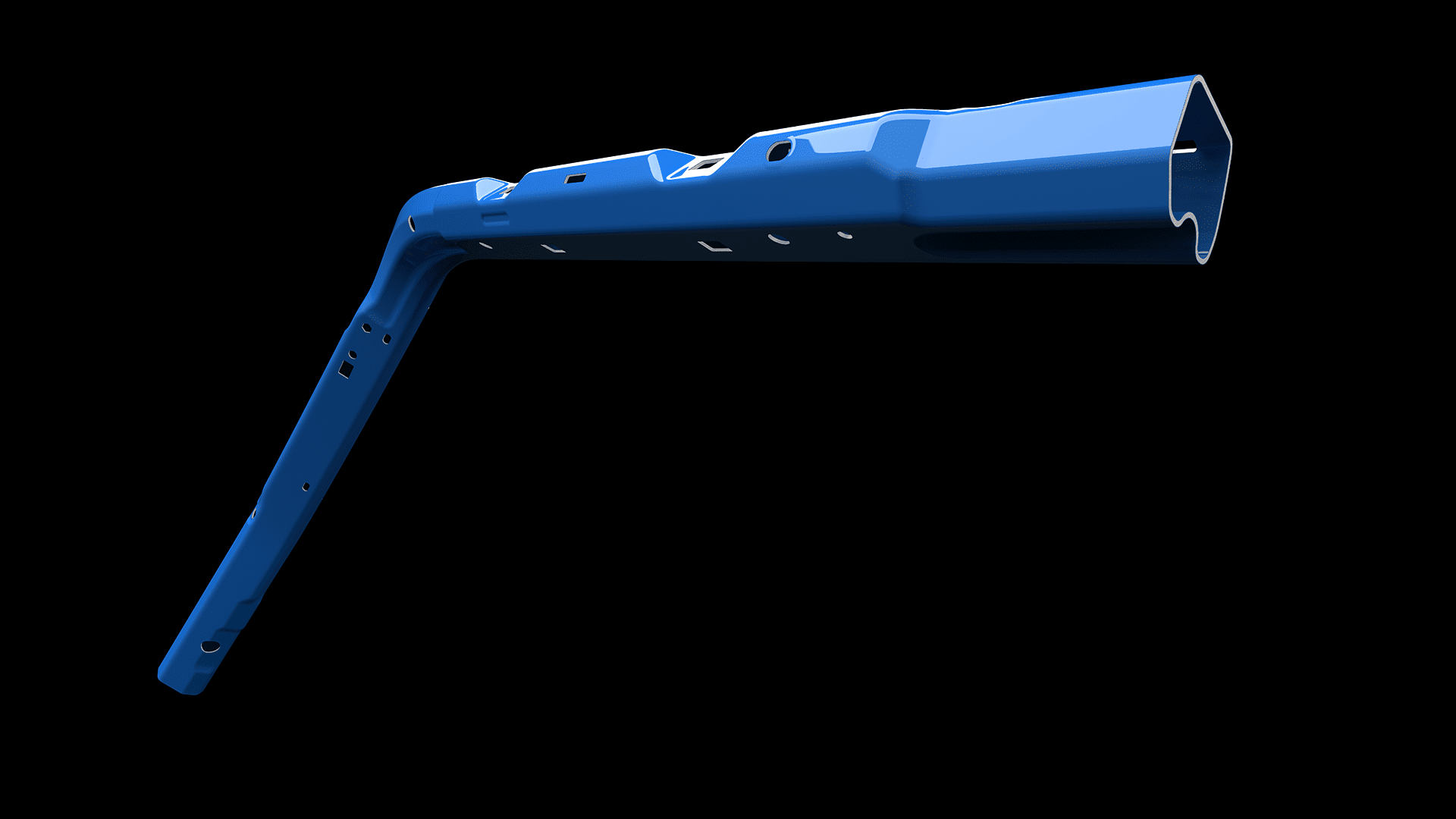

Key advantages of ACCRA™ hot-blow-form tube design

The ACCRA™ process delivers:

- Complex, hollow-profile, fully-martensitic structures at 1500+ MPa strength

- Very high strength with repeatable metallurgical and performance characteristics

- Lightweight products without the use of exotic materials

- A variable cross-section (up to a 20% transitional increase in section profile size) to optimize packaging space and structural stiffness where required

- Uniform material property throughout the component, with no heat-affected zones

- Excellent part tolerance control due to minimized residual component stress

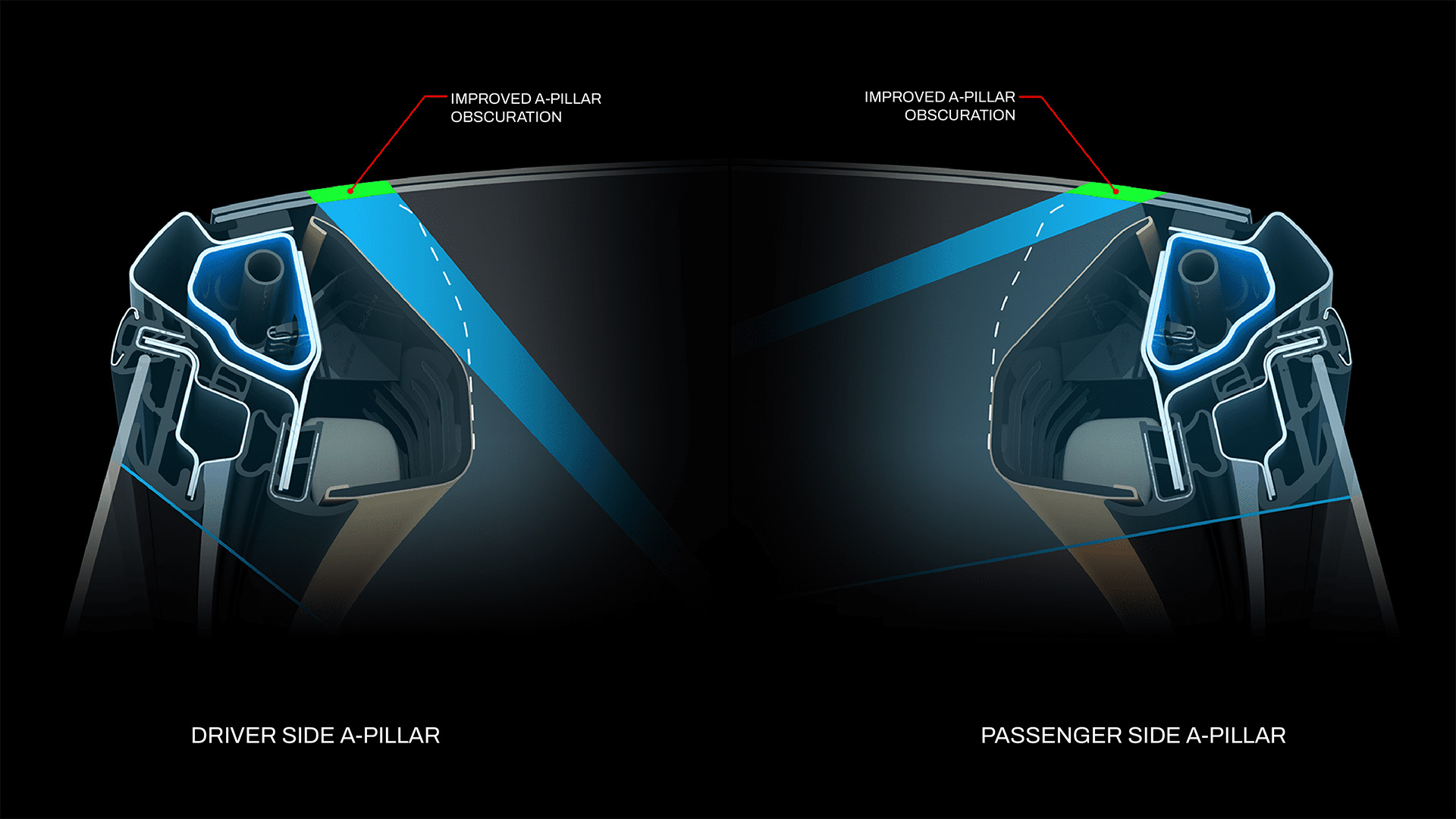

Optimized A-pillar packaging

The ACCRA™ process is well suited for production of A-pillars because:

- A reduced cross-section is achievable, providing enhanced packaging opportunities and an increased vision zone

- The internal ACCRA™ tube is designed to match or exceed performance targets of traditional stamped body structures

- Tight tolerance control of the finished structure means the windscreen can optionally be bonded directly to the ACCRA™ tube

Driver vision optimization

- The windscreen bond region can be located directly over the ACCRA™ section, optimizing packaging volume

- A-pillar trim optimization significantly improves driver vision angles

- Attachment features integrated into the ACCRA™ form eliminate the need for additional brackets

- Further improvement is possible with optimization of the door frame / A-pillar interface