ACCRA™

Formed-in strength.

ACCRA™ proprietary form-blow-hardening technology is ideal for producing complex hollow-profile structures that are ultra-strong, yet lightweight.

Multimatic produces over two million SORB tubes per year, including for the North American Ford Ranger.

ACCRA™ structures achieve 1500+ MPa strength and are well-suited for products requiring:

1

High structural performance (comparable to hot stamping/PHS) within tight packaging constraints

2

Light weight, without the cost of exotic materials

3

Closed-section assemblies with no heat-affected zones

4

Aggressive bends, sweeps or indents with dimensional stability and accuracy over long parts

5

Variability based on profile cut length

Case Study

ACCRA™ Design Benefits: A-Pillar

Balancing A-pillar vision obstruction against crash and roof-crush requirements is a major challenge in vehicle development. Read more…

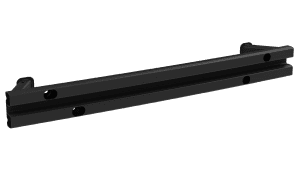

Door Beams

Door Beams

Impact Beams

Impact Beams

Roof Structures

Roof Structures